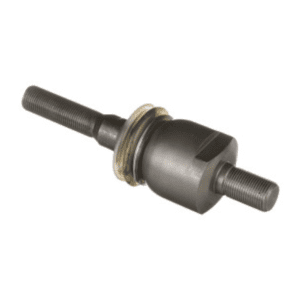

Spherical Joint for Front Axle Used in Case Construction Equipment

A spherical joint is a critical component in heavy machinery like Case Construction Equipment. Designed to connect parts and allow for multidirectional movement, spherical joints ensure that the front axle can handle the heavy stresses and loads it encounters during operation. Without these joints, vehicles would not be able to function smoothly, leading to mechanical breakdowns and operational inefficiencies. This article explores the significance of spherical joints, especially in front axles used in Case equipment, and why it’s essential to choose high-quality replacements when needed.

The function of the Spherical Joint in the Front Axle

The front axle in Case Construction Equipment requires high-performance parts to ensure optimal functionality, and the spherical joint plays a vital role in this. It allows for flexibility and smooth movement while distributing weight and pressure across the axle. These joints ensure the axle remains stable and balanced even when the equipment is operating under heavy loads.

Types of Spherical Joints

There are several types of spherical joints used in heavy machinery, including:

- Standard Spherical Bearings: Used in light to moderate load applications.

- Self-Lubricating Joints: Ideal for machines with limited maintenance opportunities.

- Heavy-Duty Joints: Designed for extreme loads and harsh working conditions.

Choosing the correct type of joint depends on the specific requirements of the machinery and the environment in which it will be used.

Spherical Joint Materials

The durability of a spherical joint largely depends on the materials used in its construction. Case Construction Equipment typically uses high-strength steel with corrosion-resistant coatings to ensure longevity. The material must be strong enough to withstand the heavy stresses of construction work while remaining resistant to wear and tear from friction and environmental factors.

Installation Process

Installing a spherical joint in the front axle of a Case machine requires precision and the right tools. Below is a simplified guide to the installation process:

- Remove the old joint: Ensure that all bolts are loosened and the joint is carefully extracted.

- Prepare the area: Clean the housing area, removing any debris or residue that could interfere with the installation.

- Fit the new spherical joint: Align the joint correctly with the axle.

- Tighten the bolts: Ensure the joint is securely fastened to avoid any operational failures.

- Test the machinery: Once installed, run a test to ensure the joint is functioning as expected.

Common Issues with Spherical Joints

Spherical joints are subjected to extreme forces, and over time, they may experience issues such as:

- Corrosion: Especially if the joint is not made from corrosion-resistant materials.

- Wear and tear: Frequent use in harsh conditions can cause deterioration.

- Misalignment: If not installed correctly, misalignment can lead to further mechanical issues.

Maintenance Tips

Regular maintenance is essential for ensuring the longevity of your spherical joint. Some tips include:

- Lubrication: Ensure joints are lubricated regularly to minimize friction.

- Inspection: Conduct routine inspections to catch any early signs of wear.

- Replacement of seals: Replace any damaged seals to prevent contaminants from entering the joint.

Signs of Wear and Tear

Several signs indicate a spherical joint may need to be replaced:

- Loose or wobbly axle movement

- Grinding noises during operation

- Visible cracks or wear on the joint itself

Why Choose Genuine Case Parts

When replacing a spherical joint, it’s essential to use genuine Case parts. Authentic parts are designed specifically for Case equipment, ensuring they meet the high standards of quality and durability that Case is known for.

Cost Analysis

Investing in a high-quality spherical joint is essential for ensuring your equipment runs smoothly. While genuine Case parts may be more expensive, they provide a better long-term investment compared to cheaper, inferior alternatives.

Where to Buy Spherical Joints

You can purchase spherical joints for Case Construction Equipment from:

- Authorized dealers

- Online marketplaces

- Specialty construction parts retailers

How to Identify Authentic Parts

Ensure the part has the Case Construction logo and part number and comes with an authenticity certificate to avoid counterfeit products.

Warranty Information

The case offers warranties on their genuine parts, providing peace of mind and protecting your investment.

Customer Reviews

Customers frequently praise Case’s spherical joints for their durability and reliability, noting that they can withstand extreme working conditions.

Conclusion

The spherical joint for front axles in Case Construction Equipment is a vital component that ensures the machine operates smoothly and efficiently. Choosing a high-quality, genuine part not only enhances the equipment’s performance but also provides long-term durability.